WAI Water Hammer & Button Bits

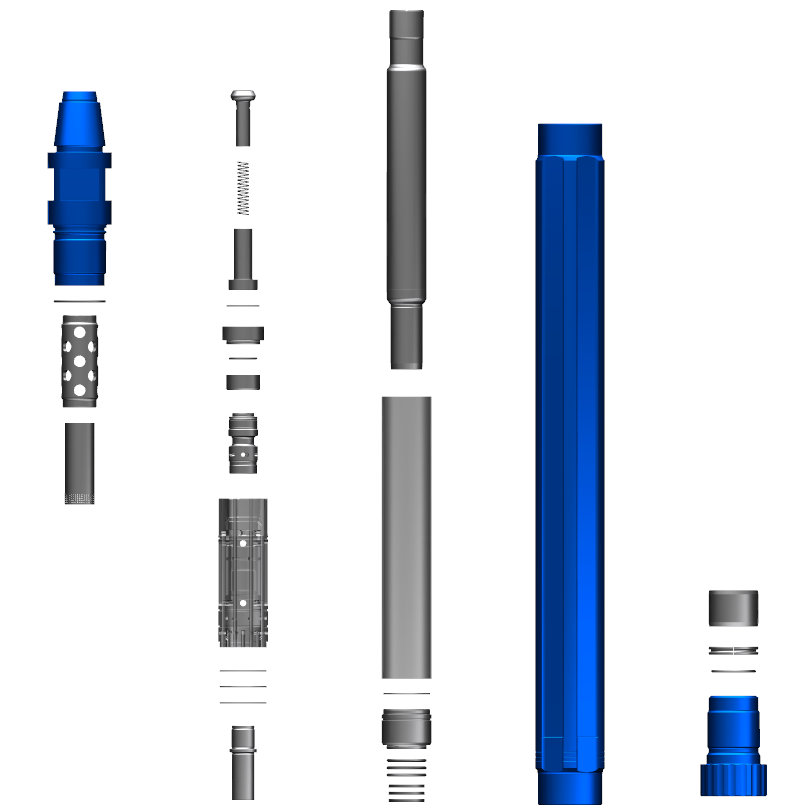

The WAI series hammer is designed to operate efficiently on fluid pressure. Compressed fluid is directed to the hammer via the rotation spindle and drill pipe. Exhaust fluid from the hammer passes through blow-holes in the drill bit and is used to flush the drilled hole. Rotation is provided by a rotation unit on the drill rig and transferred to the hammer via the drill pipe.

The drill pipe is threaded so that the drill string can be extended as the drilling advances and the hole becomes deeper. Feed force is also transmitted to the hammer via the pullback/pull-down unit and the weight of the drill pipe.

The Drill King hammer series names, XT (Extreme Tools), was developed after much research through our integrated drilling tools project. The XT series is designed to be used in a wide range of various applications in hard formations. The following represents a few highlights.

Key Features

- Premium Alloy developed using a proprietary chemistry for the longest lasting tools in the market

- Low Maintenance: Simple service ECO kits for self-service schedules

- Hi-frequency drilling for fastest penetration rates

- Customizable to optimize performance in open hole or cased hole projects

- Bit sizes 3 ½ - 10 ½ / 89mm - 267mm

- Optional smooth wear sleeve or with integrated stabilizing ribs

- Integrated stabilizing ribs for minimized hole deviation

- Lower Operating costs due to reduced energy consumption

- Environmentally friendly drilling

- Will drill a straighter hole than a conventional air hammer